Products

Solar tanks

Tank accessories

Priority flap

Priority flap

A special priority flap allows the upper section of the main tank to be priority-charged when connected to an expansion tank. Can be used with a maximum boiler output of 70 kW. When using a priority flap without a PVS corrugated connection pipe, the uppermost connection line between the main tank and the expansion tank has to be fitted on site. Attention should be paid to the flow direction and horizontal installation.

PVS corrugated connection pipe

PVS corrugated connection pipe

The corrugated pipe is used to connect 2 tanks and may only be installed in a horizontal position with no sagging (avoid thermosiphon action)! Guide plates are included in the scope of delivery. The pipe nipples should be sealed properly with hemp and sealing compound! Including 19 mm rubber insulation. Transmission capacity up to 50 kW.

Download

Inflow pipe

Inflow pipe

The inflow pipe provides a steady flow into the backup tanks. The distribution is optimised by the conical shape. The surface of the lance is cathodic-dip painted (EPD-coated). It can be installed in sleeves with a female thread Rp 1½”. Assembly proceeds with the respective sleeves for the boiler or heating process.

Download

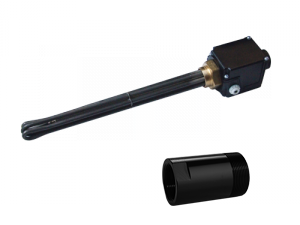

EEH Electric screw-in heating element

EEH Electric screw-in heating element

Electrical heating element for enamelled boiler and tank, with 6/4" male thread and 132 mm unheated zone starting with the sealing area. Heating elements made of high-corrosion-resistant chrome-nickel steel 2.4858 (AISI B424) suitable for up to 10 bar operating pressure and for use in containers with up to 100 mm insulation. The extension sleeve required for this purpose is available as an accessory (reduction from 2", Item. No. 1610609). The ambient temperature at the housing must not exceed 80°C. Protection class IP 44 Externally-located temperature control unit (approx. 30 to 75°C) with frost-protection function and integrated excess temperature protection (98°C-6K) incl. RESET function. The electrical connection is by means of screw terminals. Connected voltage 400 V, 3/N/PE, 50/60 Hz or 230 V, 1/N/PE, 50/60 Hz.

VM extension sleeve

for EHH electric screw-in heating element

For installation of an electric screw-in heating element in a Pro-Clean®, Pro-Heat or FS tank. EPD-coated.

Download

EFH Electric flange heating

EFH Electric flange heating

Electrical heating element for large tank in flange version (DN 200, outer diameter 280 mm, pitch circle diameter 245 mm) and 135 mm unheated zone starting with the sealing area. Heating elements made of high-corrosion-resistant chrome-nickel steel 2.4858 (AISI B424), suitable for up to 10 bar operating pressure. The ambient temperature at the housing must not exceed 80°C. Protection class IP 44 Externally-located temperature control unit (approx. 30 to 75°C) with frost-protection function and integrated excess temperature protection (98°C-6K) incl. RESET function. The electrical connection is by means of screw terminals. Connected voltage 400 V, 3/N/PE, 50/60 Hz (EFH 12) or 2 x 400 V, 3/N/PE, 50/60 Hz (EFH 18, EFH 30)

Download

Plate heat exchanger

Plate heat exchanger

The plate heat exchangers are made of corrugated stainless-steel plates. Antifreeze (solar side) or water (secondary side) flows through the plates in the counter flow principle, thereby achieving very effective heat transmission. All stainless steel plates, as well as the solid connection plates with their implemented connections (also made of stainless steel), are combined into one unit by a copper plomb.

Download

Domestic hot water mixing valve

A self-actuating thermostatic domestic hot water mixing valve acts as a central mixing unit and ensures a constant mixed water temperature at the point of withdrawal. Scalding at the point of withdrawal is thereby avoided even at high tank temperatures. Special valve seals at the control piston reduce unwanted admixtures to a minimum*, resulting in maximum utilisation of the tank temperature. Long service life thanks to high-quality plastics and non-stick coatings against limescale. Infinitely adjustable

target temperature.

Mode of function

The mixing valve is supplied with hot water from a tank and with cold water from the line network. The temperature of the mixed water is registered by a thermostatic expansion element. A deviation in the temperature of the mixed water from the target value will cause the expansion element to move the control piston, and thereby regulate the supply of hot and cold water until the mixed water temperature corresponds to the target value.

Benefits

- Constant water temperature at the point of withdrawal

- Self-actuating mixing function without supplementary energy

- Infinitely variable adjustment of the mixed water temperature

- High control precision

- Protection from scalding

- High kVS values

- Very low cold water leakage rate

- Non-stick coating of the valve housing against limescale

- Locking option of the target value setting

- Can be used as a diverting valve

- No additional seals are required when used as return flow inhibitor

- Return flow inhibitors are secured against loss

*When the hot water is 3 K below the set mixed water temperature, then the cold water leakage rate = 0. Otherwise the admixture is limited to max. 3 K.

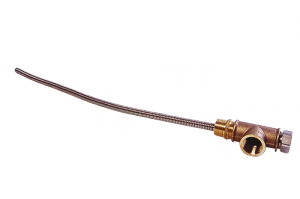

Circulation lance

Circulation lance for tanks with corrugated stainless-steel pipe.

When hot water circulation is planned in house installations – where hot water is available from the tap at all times – a circulation lance must be connected in the domestic hot water line of stratified or fresh water tanks with corrugated stainless-steel pipes.

The WT 5 circulation lance is suitable for preheating the domestic hot water with up to 5 kW circulation losses. The lance is delivered complete with a T-piece and a hexagon nipple and is compliant with the "Directive on the quality of water intended for human consumption" 98/83/ EC. The T-piece and hexagon nipple are DVGW-tested (German Technical and Scientific Association for Gas and Water).

Download

Circulation unit

This pump group provides hot water circulation in sanitary systems The advantages are the immediate availability of hot water (lower water consumption) and protection from Legionella. The hot water temperature is always held constant by action of the integrated thermostatic mixing valve. A bypass from the circulation pipe to the mixing valve minimises the energy loss in the hot water circulation. Unfavourable fluid flow is prevented by five integrated check valves. The ready-to-install component is fully insulated and assembled. The circulation pump can be adjusted to the desired circulation temperature by means of the in-built thermostat.

Download

Fresh water module FWM

Fresh water module

The fresh water module guarantees permanently fresh and vital hot water. Required quantities can be supplied without any waiting time or temperature fluctuations. A long service life is ensured by high-quality components and protection against limescale

deposition due to thermal conditions. Product advantages: Prevents the development of Legionella bacteria, very fast response times, tank or wall installation, for 1 to 3 family households, separable flat sealing system connection, high tap quantities through utilisation of a large heat exchanger.

Download

Circulation pump

Circulation pump

Attachable to the fresh water module using a simple plug-in system. Temperature selection switch and time switch are integrated.

Download

Control thermostat

Control thermostat

The control thermostat, incl. immersion sleeve with1/2" male thread, is used for floating switching of an electrical device depending on the tank temperature.

Control range 0 – 90 °C, 1 change-over contact

Download

S1 impressed current anode

S1 impressed current anode

An impressed current anode is a long-term alternative to a sacrificial anode. It is based on the most advanced technology and provides a lasting, electronically controlled protective current for your tank. The continuous protective current is controlled by a potentiostat and is supplied by a titanium electrode in the tank. This provides safe protection against corrosion in all TiSUN® enamelled steel tanks.

An effective protective current must be adjusted exactly to the individual conditions in the hot water tank at all times. To prevent it from being too high or too low, the potentiostat automatically adjusts the current based on the individual operating conditions. Over- or under-protection is prevented in this manner. The current is fed via a mixed oxide coated titanium electrode, which is practically wear-free.

Download

Sludge separator for heating circuits

Sludge separator for heating circuits

The sludge separator removes sludge particles with dimensions greater than 5 μm from the system water. The captured sludge particles can be rinsed away while the system is in operation. When the drainage tap is opened the accumulated contamination can be quickly pushed out. The ready-to-use insulation has a low thermal conductivity as well as excellent temperature stability and can be easily fitted to the sludge separator by separation along the cutting marks with a cutting knife.

Download

Microbubble de-aerator for heating circuits

Microbubble de-aerator for heating circuits

The microbubble deaerator has been developed for fully automatic removal of air from water/glycol mixtures (max. 40% glycol). The readyto-use insulation has a low thermal conductivity and excellent temperature resistance and can easily be fitted to the bubble deaerator by cutting at the cutting marks (carpet knife).

Download

Boiler safety group

Boiler safety group

Safety Group 24 serves to provide optimum protection against pressure excesses in closed drinking water heaters (TWE), in compliance with DIN 1988, part 2; DIN 4753, part 1 and DIN EN 1488. It meets noise protection standards in compliance with DIN 4109 (noise protection in highrise construction) Class 1 and contains, in compact form, all the components that must be fitted to drinking water heaters as stipulated by DIN 1988 and DIN EN 1488. The pressure relief valve protects the downstream drinking water heater and the return flow inhibitor prevents the heated drinking water from flowing back.

Download

Boiler safety centre

Boiler safety centre

The boiler safety centre protects closed drinking water heaters (TWE) to max. 560 l volume, in compliance with DIN 1988, part 2; DIN 4753, part 1; DIN 4807, part 5 and DIN EN 1488. In compliance with DIN 1988 and DIN EN 1488 it contains the components that are required to be fitted to the input side of drinking water heaters. This equipment includes a flow unit with integrated maintenance shut-off, as well as a compact flowthrough membrane expansion tank (MAG) with a nominal volume of 12 l or 18 l, in compact form.